How to make Rope Protective Pad

Materials for making - Polyester Web Sling Band(10 ton, 1 ton), 3mm bolt, nut, knife, gas burner, 2mm cord, grinder.

Today, I'm blogging how to make rope protective pad because I need it for my 100m rope.

For me, It could make it without any problem cause I have an old protective pad which one of my team members already made it. Also, I have all the tools that are needed for making it in my office so only spent money for web slings.

Taking all the seams out that are connecting with two layers of 10 ton web sling so make it one layer and then cutting it proper size of length.

and slightly burn each side of cutted web sling so it wouldn't be taken seams out.

and make supporting rope stand using 1 ton web sling in order to make rope fixed while working.

Approximate size for cutting is about 20~30cm and also slightly burn each side of slings. it gonna to be folding into two then it become about 10~15 cm.

and make supporting rope stand using 1 ton web sling in order to make rope fixed while working.

Approximate size for cutting is about 20~30cm and also slightly burn each side of slings. it gonna to be folding into two then it become about 10~15 cm.

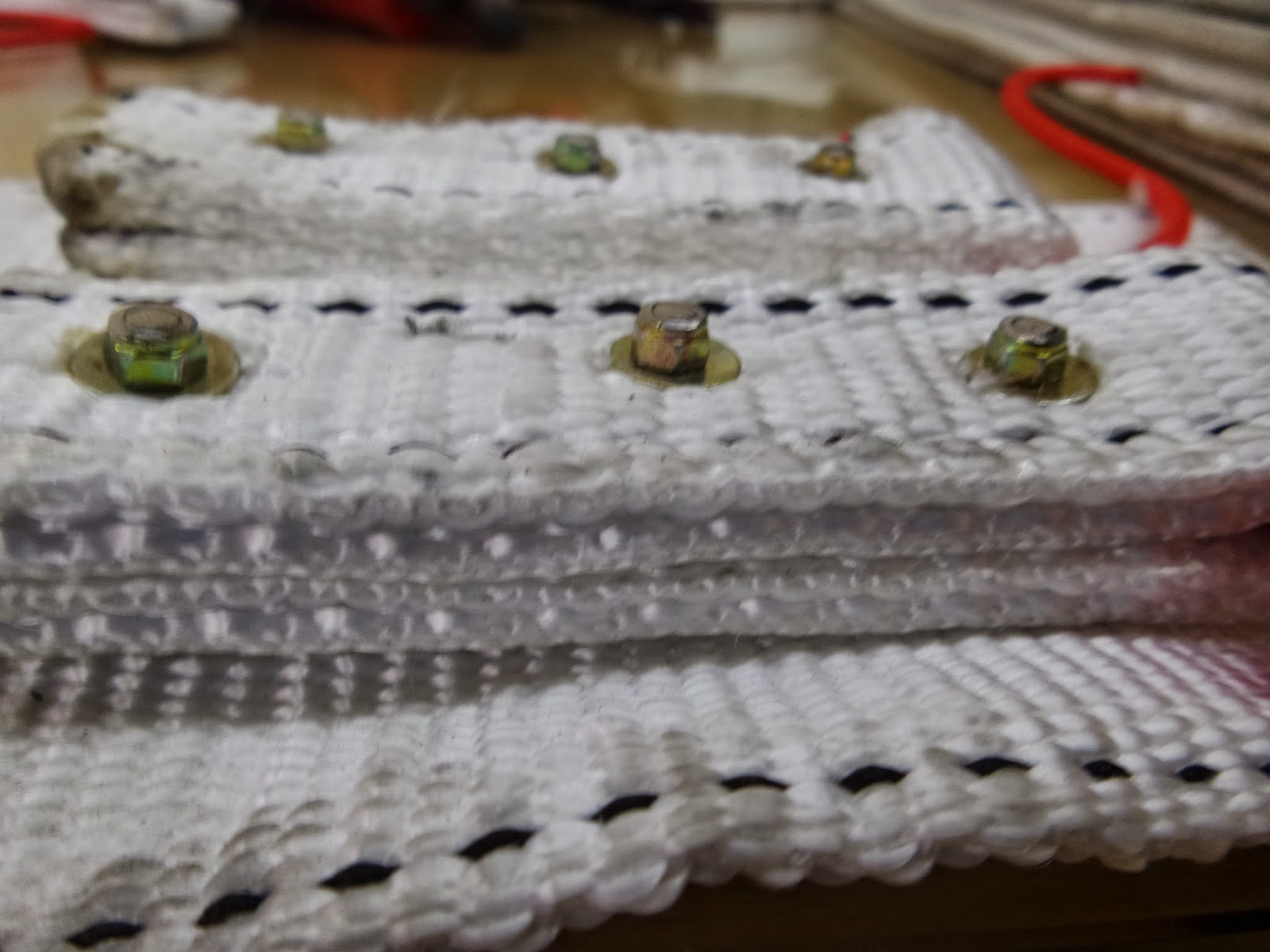

and make three wholes in a row with red-hot drill bit for fixing on 10ton sling with bolt and nut and put the 2mm cord between folded 1ton sling.

and put its placement from the end of 10ton sling and locate two of it.

Remain proper width between two of them because two rope should be fixed in that space.

Remain proper width between two of them because two rope should be fixed in that space.

Connect all the bolts and nuts in the six wholes and tighten up the screws firmly until holding it. It's better to make the bolt's head going downside of the pad, because we should cut it out the rested pieces of bolts after screwing up with grinder.

and then, we should make another rope fixing code where the other side of what we made in advance. Cut a code about 30~40cm, and make that one side is 10cm longer than another side. then longer side would be winded a rope once more than another side so it will prevent the rope to move.

Lastly, I put my name on it so it would not be mixed with other teammates', I made 4 of these, that's enough to use because every teammates have on their own. If you have more creative idea to develop this rope protector please share with me!

Good luck!